Chapter 10: Extending

The Organization- Supply Chain Management (SCM)

BASICS OF SUPPLY CHAIN

Supply chain: consists of all parties

involved, directly or indirectly in the procurement of a product or raw

material.

Supply Chain Management: the

management of information flows between and among stages in a supply chain to maximize

total supply chain effectiveness and profitability

The supply chain

has three main links:

1.

Materials flow from

suppliers and their "upstream" suppliers at all levels

2. Transformation of

materials into semi-finished products, or the organization’s own production

processes

3.

Distribution of products

to customers and their downstream customers at all levels

Figure

1: A typical supply chain

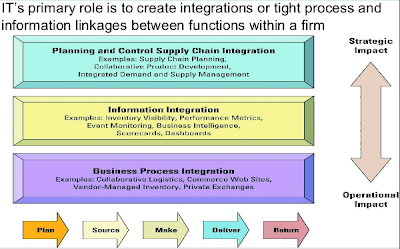

INFORMATION TECHNOLOGY’S ROLE IN THE SUPPLY CHAIN

Information technology’s primary role in SCM is creating the integration or tight process and information linkages between functions within

a firm such as marketing, sales, finance, manufacturing, and distribution – and

between firms, which allow the smooth, synchronized flow of both information

and product between customers, suppliers and transportation providers across

the supply chain.

Figure 2: The five basic

supply chain management components.

The five basic

supply chain management components:

1. Plan

|

·

It is the strategic portion of supply chain

management.

·

A company must have a plan for managing all

the resources that go toward meeting customer demand for products/ services.

·

A big piece of planning is developing a set

of metrics to monitor the supply chain so that it is efficient, less cost and

deliver high quality and value to customer.

|

2. Source

|

·

Companies must carefully choose reliable

suppliers that will deliver goods and services required for making products.

·

Companies must also develop a set of pricing,

delivery and payment processes with suppliers and create metrics for

monitoring and improving the relationship.

|

3. Make

|

·

This is step where companies manufacture

their products/ services.

·

This can include scheduling that activity

necessary for production, testing, packaging and preparing for delivery.

·

This is by far the most metric-intensive

portion of the supply chain, measuring quality levels, and production output

and worker productivity.

|

4. Delivery

|

·

This step is commonly referred as logistics.

·

Logistics: the set of processes that plans

for and control the efficient and effective transportation and storage of

supplies from suppliers to customers.

·

During this step, the companies must be

able to receive orders from customers, fulfill orders via a network of

warehouse, pick transportation companies to deliver the products and

implement a billing and invoicing system to facilitate payments.

|

5. Return

|

·

It is the most problematic steps.

·

The companies must create a network for

receiving detective and excess products and support customers who have

problems will deliver products.

|

Figure 3: The integrated

supply chain

Factors driving supply chain management

1. VISIBILITY

· Supply

Chain Visibility:

the ability to view all areas up and down

the supply chain. Changing supply chains requires a comprehensive strategy

buoyed by information technology. Organizations can use technology tools that

help them integrate upstream and downstream, with both customers and suppliers.

·

The

bullwhip

effect occurs when distorted product demand

information passes from one entity to the next throughout the supply chain.

2. CUSTOMER

BEHAVIOR

· The behavior of

customers has changed the way businesses complete. Customers will leave if a

company does not continually meet their expectations. They are more demanding

because they have information readily available, they know exactly what they

want, and they know when and how they want it.

· Demand

planning software generates demand forecasts using statistical tools and

forecasting techniques.

· Companies can respond

faster and more effectively to consumer demands through supply chain

enhancements such as demand planning software.

· Once an organization

understands customer demand and its effect on the supply chain it can begin to

estimate the impact that its supply chain will have on its customers and

ultimately the organization’s performance.

3. COMPETITION

SCM software can be

dividing into:

i.

Supply

chain planning (SCP) software uses advanced mathematical algorithms to improve the flow

and efficiency of the supply chain while reducing inventory. SCP depends

entirely on information for its accuracy.

ii. Supply

chain execution (SCE) software automates the different steps and stages of the supply

chain. This could be as simple as electronically routing orders from a

manufacturer to a supplier.

v Both of the will increase a company’s ability to compete

Figure 4: Supply chain

planning and supply chain execution software’s correlation to the supply

4.

SPEED

· These systems raise the

accuracy, frequency and speed of communication between suppliers and customers,

as well as between internal users.

· Another aspect of speed

is the company’s ability to satisfy continually changing customer requirements

efficiently, accurately and quickly

·

Timely and accurate

information is more critical to business than ever before.

Figure 5: Factors fostering speed

SUPPLY CHAIN MANAGEMENT SUCCESS FACTORS

· To succeed in today’s

competitive markets, companies must align their supply chain with the demands

of the markets they serve.

· Supply chain performance

is now a distinct competitive advantage for companies proficient in the SCM area.

Figure 6: Seven

principles of SCM

The following are

keys to SCM success:

i.

MAKE THE SALE TO

SUPPLIERS

The hardest part of any SCM system is its complexity because

a large part of the system extends beyond the company’s walls. Not only will the

people in the organization need to change the way they work, but also the

people from each supplier that is added to the network must change. Be sure

suppliers are on board with the benefits that the SCM system will provide.

ii.

WEAN EMPLOYEES OFF

TRADITIONAL BUSINESS PRACTICES

Operations people typically deal with phone calls, faxes and

orders scrawled on paper and will most likely want to keep it that way.

Unfortunately, an organization cannot disconnect the telephones and fax

machines just because it is implementing a supply chain management system. If

the organization cannot convince people that using the software will be worth

their time, they will easily find ways to work around it, which will quickly

decrease the changes of success for the SCM system.

iii.

ENSURE THE SCM SYSTEM

SUPPORTS THE ORGANIZATION GOALS

It is important to select SCM software that gives

organizations an advantage in the areas most crucial to their business success.

If the organizational goals support highly efficient strategies, be sure the

supply chain design has the same goals.

iv. DEPLOY IN INCREMENTAL

PHASE AND MEASURE AND COMMUNICATE SUCCESS

Design the development of the SCM system in incremental

phases. For instance, instead of installing a complete supply chain management

system across the company and all suppliers at once, start by getting it

working with a few key suppliers, and then move on to the other suppliers.

Along the way, make sure each step is adding value through improvements in the

supply chain’s performance. While a big-picture perspective is vital to SCM

success, the incremental approach means the SCM system should be implemented in

digestible bites and also measured for success one step at a time.

v.

BE FUTURE ORIENTED

The supply chain design must anticipate the future state of

the business. Because the SCM system likely will last for many more years than

originally planned, managers need to explore how flexible the systems will be

when (not if) changes are required in the future. The key is to be certain that

the software will meet future needs, not only current needs.

No comments:

Post a Comment